Products

HMB(Hinode Micro Bubbler)

Micro(µ)bubbles are fine air bubbles with diameters in the range between ten and several tens of microns.Small bubbles are efficiently soluble in liquids, resulting in higher dissolved oxygen and improved water quality.

Micro(µ)bubbles are fine air bubbles with diameters in the range between ten and several tens of microns.Small bubbles are efficiently soluble in liquids, resulting in higher dissolved oxygen and improved water quality. Micro/nanobubblesare air bubbles of ten microns to 200 nanometers in diameter. They may possibly have the properties of both types of fine bubble.

Micro/nanobubblesare air bubbles of ten microns to 200 nanometers in diameter. They may possibly have the properties of both types of fine bubble. Nano (n) bubbles are ultrafine air bubbles of 200 nanometers or less in diameter (1 nanometer is one billionth of a meter).They are expected to be applied to a wide variety of fields in the future, including agriculture and medicine.

Nano (n) bubbles are ultrafine air bubbles of 200 nanometers or less in diameter (1 nanometer is one billionth of a meter).They are expected to be applied to a wide variety of fields in the future, including agriculture and medicine.

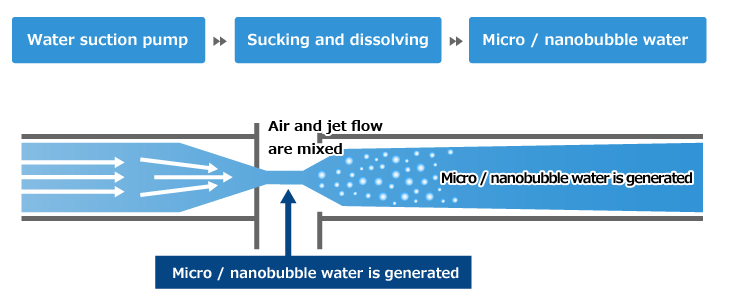

HMB is a groundbreaking fine air bubble (microbubble) generator using

ejector + air mixing jet + Venturi-tube principle.

- Features

-

- Supplying high-concentration gas (including air)

HMB can produce a large quantity of microbubbles and supply high-concentration air. - Installation conditions

HMB can be installed either on land or underwater, as it is connected to a pump and is capable of self-suction by using a special ejector mechanism. A variety of models are available according to the required volume. - Free of maintenance

HMB can be used for salt water, fresh water, and contaminated water (all stainless, SUS304), and the pipes will not become clogged with inflow from the pump. - Introduction of air bubble stabilizer

By introducing an air bubble stabilizer through a small-diameter pipe, more stabilized microbubbles are generated. - Installation

HMB and pumps can be installed either on land or underwater.

- Supplying high-concentration gas (including air)

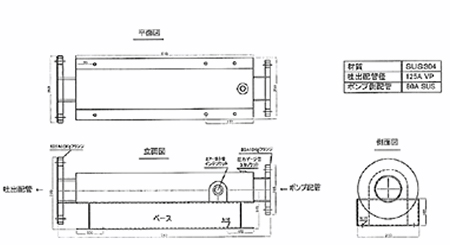

- External view of HMB structure (Example: HMB72)

-

- Structural conceptual diagram

-

Principle

HMB is a groundbreaking fine-air-bubble (including microbubbles) generator that solves cavitation by using the bubble collapse principle.(Patent applied for the air-bubble-stabilizer mixing type)

How to use HMB

- For effluent treatment, purification of ocean, lakes, and marshes, and cultivation

-

1. For effluent treatment and cultivation

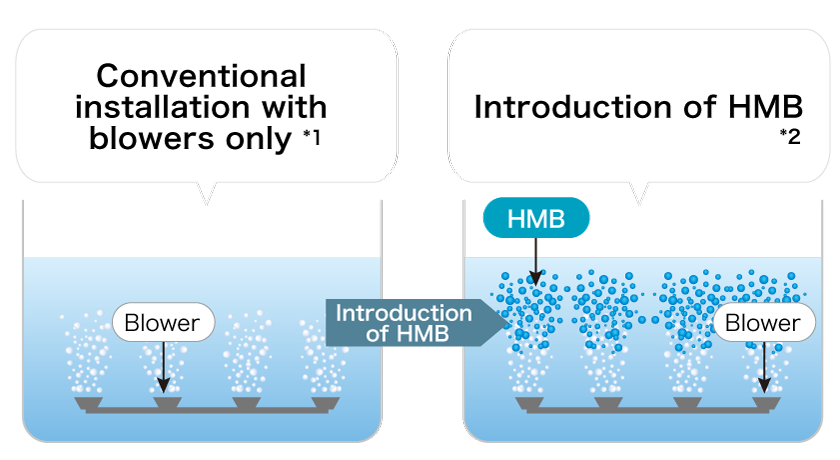

*1:Blowers are not capable of supplying sufficient oxygen in viscous water in which oxygen is insoluble, or in a tank with shallow water, causing a lack of oxygen!

*2:Microbubbles are generated,

improving the oxygen dissolution efficiency to 160%.Water depth Oxygen

solubility(%) with blowersOxygen

solubility(%) with HMB + blowers1m 1.1 1.78 1.7m 2.7 4.5 2.7m 4 6.3 (Experiment data)

2. Features of micro/nanobubbles (fine air bubbles)

- ・Features of micro/nanobubbles (fine air bubbles)

- ・Finer air bubbles have low floating speed.

- ・Air bubbles of 10 µµm (micrometer) in diameter float at a rate of 2 mm/min.

- ・Air bubbles are negatively charged and absorb underwater suspended substances.

3. Utilization of fine air bubbles

- ・Microbubbles absorb fine dirt and oil: microbubbles have excellent absorptivity, especially to oil. By using them for cleaning, oil can be removed without using detergents.

- ・Oil repels water, but sticks to air: By collecting oil with bubbles on the surface of water and removing it, the clean water can be reused.

- ・Various properties: it is used in a wide variety of applications including factory effluent, water quality improvement in dams and ponds, hot springs, confectionery manufacturing, and sake brewing.

HMB system diagram

Test record

Discharged

water volumeSucked air

volumeWater volume

calculated based on

the nozzle diameter

and water pressure

(error rate of 5% or less)Actual

measurement

valueActual

measurement

value of clear water,

Straight pipe 1.5m,

lift 0mPump water

pressure

(Mpa)Nozzle

diameter

(mm)Discharged

water volume

(ℓ/min)Discharged

water volume

(ℓ/min)Rated value

(m3/h)Actual

measurement

value

(m3/h)0.09 45.5 1,301 39 43 0.08 45.5 1,227 1,220 36.8 40 0.07 45.5 1,149 34.3 38 Submerged pump

driving modelsHMB pipe diameter

from pumpDischarge pipe

from HMBDrive pump

(kW)Discharged

water volume

(m3/H)Air suction

volume

(m3/H)HMB27-C/D-2.2 65A SUS 80A 1.5~2.2 26~27 15~16 HMB58-C/D-3.7 80-100 SUS 100A 3.7 56~58 33~34 HMB72-C/D-5.5 80-100A SUS 125A 5.5 70~72 42~43 HMB130-C/D-7.5 100A SUS 150A 7.5 120~130 76~78 All models SUS304 Land pump

driving modelsHMB pipe diameter

from pumpDischarge pipe

from HMBDrive pump

(kw)Discharged

water volume

(m3/H)Air suction

volume

(m3/H)HMB18-V-1.5 50A SUS 65A 1.5 17~18 10~11 HMB27-V-2.2 75A SUS 80A 2.2 26~27 15~16 HMB49-V-3.7 65A SUS 100A 3.7 47~49 28~29 HMB72-SL-5.5 80-100A SUS 125A 5.5 70~72 42~43 All models SUS304

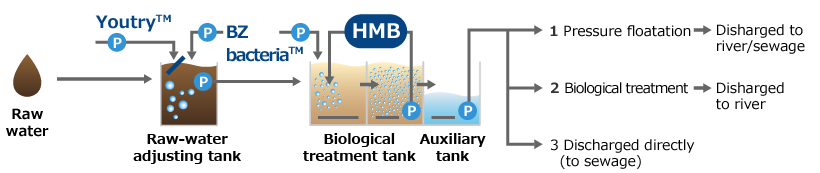

HMB&Dispersed Bacteria Treatment Method

Effluent is treated with dispersed bacteria by using HMB.

Effluent is treated with dispersed bacteria by using HMB. Sufficient oxygen prevents the generation of bad odors, facilitates oxygen supply, decreases the amount of aeration, and conserves energy.

Sufficient oxygen prevents the generation of bad odors, facilitates oxygen supply, decreases the amount of aeration, and conserves energy. This makes the maintenance and management far simpler.

This makes the maintenance and management far simpler.

Effluent treatment with dispersed bacteria

- Features (outline of the system)

-

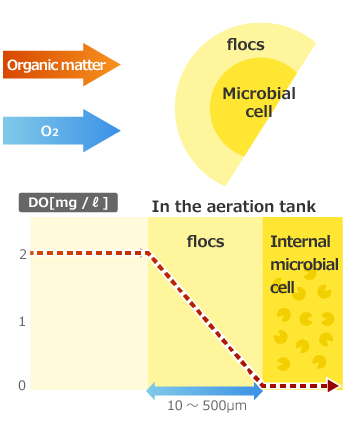

- What is the dispersed bacteria treatment system?

- All the bacteria in a biological treatment tank are dispersed to treat water without forming flocs.HMB is an essential component of the system; it prevents floc formation and supplies oxygen efficiently.It does not require the usual aeration and settling tanks, and there is no return sludge.

-

- Features

-

- Increased treatment performance with dispersed bacteria (HMB + dispersed bacteria): system and features

-

- Generated microbubbles increase the dissolved oxygen level at once (freshwater test, 9 mg/ℓ).

- Powerful mixing effect enhances oxygen dissolving efficiency from blowers (internal test, 160%).

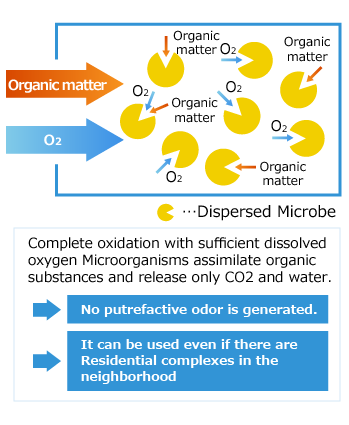

- The BZ bacteria that are contained in the microorganism agent degrade carbohydrate, protein, and oil components efficiently.

- It is fully aerobic and organic substances are turned into water and carbon dioxide, generating none of the odors that are associated with effluent treatment plants.

(CXHYOZ + O2 → CO2+ H2O -⊿H)

Conventional activated-sludge method Dispersed bacterial treatment system

Dispersed bacterial treatment system

- Example of application

-

- Introduction of the dispersed bacteria system

-

Treatment method: dispersed bacteria treatment system + pressure floatation treatment

Site of delivery: factory producing boxed lunches and prepared food for convenience stores (production volume: 100,000 packages per day)

Drainage volume: 300 m3/ day (discharged to sewage) Delivery point: Saitama Prefecture -

Dispersed bacteria tank

Pressure floatation equipment

(floating tank)

Installation of HMB on land

When cooking

riceDuring production

of prepared foodMeasurement

tankPressure floatation Non-chemical

injectionChemical

injectionBOD(mg/ℓ) 900 4700 310 120 7 COD(mg/ℓ) 380 5400 340 160 17 Hexane extracts

(mg/ℓ)140 610 36 7 <1 SS(mg/ℓ) 436 675 680 240 10 pH 6.15 6.2 6.69 6.96 6.62 EC(ms/m) 48.8 181.7 71.2 70.5 112.7 Comparison with the

conventional activated-sludge method(*The cost comparison is based on our company’s data.)

Dispersed bacteria treatment method Conventional method Facilities Fewer facilities are required

- ・Untreated water tank→Biological treatment→(Coagulation separation)→Discharge

- ・There is no settling tank and return sludge

- ・Treatment of organic substances: dispersed bacteria

- ・Coagulation separation / membrane

Full facilities for the activated-sludge method are required

- ・Untreated water tank→Adjusting tank→Aeration tank→Settling tank→Discharge

- ・There is return sludge

- ・Treatment of organic substances: floc-forming bacteria

- ・Solid–liquid separation method / membrane

Features Operation and maintenance is easy

No problems occur

→Management of instruments for measuring pH, DO, and ORP: reduced maintenance cost- ・Fully aerobic⇒No odors are generated

- ・(Dispersed bacteria) Non-flocculated bacteria⇒more contact with substrate

Operation and maintenance is difficult

Many problems (including bulking, load variation, and water temperature variation)

Discharge of treated wate→olid–liquid separation technology requires the floc-optimization management: increased maintenance cost- ・Anaerobic degree is high within the floc⇒malodor

- ・Formation of floc⇒more aeration volume than necessary Inefficient treatment

Operation and maintenance Energy saving operation

- ・Amount of required air: amount of electricity is 2/3*

- ・Running cost: Simple management

- ・Sludge generation amount: reduced

- ・Initial cost: 50–60% of the conventional method*

- ・Total running expense: 65–75% of the conventional method*

High-energy operation

- ・Amount of required air is large⇒liquidity of floc: Large amount of air

⇒large amount of electricity - ・Running cost: many problems occur, including bulking

⇒Agents are required to solve problems - ・Sludge generation amount: approx. 40% of BOD*

- ・Initial cost: large area is required for the site

※Comparison within the company

- Installation method

-

The basic design of the dispersed-bacteria treatment facilities is provided by HINODE SANGYO CO., LTD.

Refer to the HMB catalog for the drainage capacity of the microbubbles.

Contact us for the capacity of the installed HMB, as this is a matter of technical know-how.

Both underwater and land installation types are available. Consult us with your specifications.

HMB&Existing Facilities Enhancement System

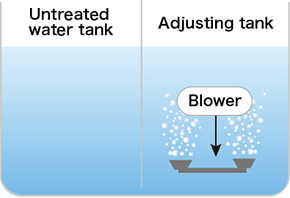

Adding the function of an aeration tank to an adjusting tank by using HMB (microbubble generator)

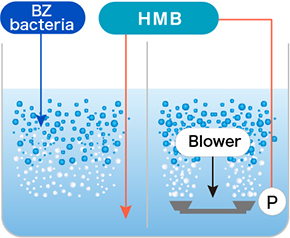

HMB is installed in the activated sludge facility currently in operation, and BZ bacteriaTM are added to improve the performance of the aeration tank functions. This enhances the treatment performance dramatically.

- Features

-

- While the existing untreated water tank and adjusting tank play their respective roles as tanks, they can also double as aeration tanks.

→The aeration tank volume is increased, improving the treatment performance - By adding the BZ bacteriaTM, the treatment performance of BOD and hexane extracts can be enhanced.

- Activation level is increased by introduction of fine air bubbles in the latter aeration tank, enhancing the treatment performance.

- With the BZ bacteriaTM + YoutryTM added, oil balls can be eliminated.

- HMB + ozone

-

Introduction of appropriate amount of ozone is known to generate the following features.

- Decomposition of persistent substances (including fat and oil) is improved.

- Decolorization is enabled by ozone oxidation.

- Sterilization of liquid is enabled (locally).

- While the existing untreated water tank and adjusting tank play their respective roles as tanks, they can also double as aeration tanks.

- Functions

-

When the production equipment of a factory is enhanced while the treatment performance of the effluent treatment facility remains insufficient, the treatment performance can be improved by adding the HMB between the untreated water tank and the adjusting tank instead of an aeration tank.

The outline of the installation is as shown in the diagram below. - How to use

-

Untreated water tank/adjusting tank

In a tank with shallow water, blowers are used for agitation

DO is insufficient as an aeration tank

HMB installation and introduction

The microbubbles turn the process into an aerobic one, and the treatment performance is improved with the BZ bacteria added.

(Sludge is not returned here)

- Application examples

-

- Practical examples of HMB installation

-

Practical example 1

Treatment method: HMB system (with the existing equipment modified)

Site of delivery: factory producing udon noodles for professional use

Drainage volume: 700 m3per day

A microbubble generator installed underwater

Fine bubbles are generated

and dispersion efficiency is increased -

Practical example 2

Treatment method: HMB system + ozone treatment

Site of delivery: factory producing various types of Chinese food

Drainage volume: 400 m3per day (discharged to sewage)

A microbubble generator installed on land (top and bottom)

Comparison of treatment with BZ bacteria (NEO) only and with HMB in the food factory 1*

Untreated water Treatment with

NEO onlyCutting rate Treatment

with HMBCutting rate BOD 3000mg/ℓ 2000mg/ℓ 33% 1500mg/ℓ 50% N-H 200mg/ℓ 120mg/ℓ 40% 100mg/ℓ 50% SS 850mg/ℓ 900mg/ℓ - 680mg/ℓ 20% Comparison of treatment with microbubbles only and with HMB + BZ bacteria (NEO) in the food factory 2*

Untreated water Treatment with

microbubbles

onlyCutting rate Untreated water Treatment with

HMB +

BZ bacteriaCutting rate BOD 1300mg/ℓ 1100mg/ℓ 15% 1900mg/ℓ 860mg/ℓ 55% N-H 170mg/ℓ 80mg/ℓ 52% 77mg/ℓ 32mg/ℓ 58% SS 720mg/ℓ 610mg/ℓ 15% 900mg/ℓ 450mg/ℓ 50% - Installation method

-

The basic design of the dispersed-bacteria treatment facility is provided by HINODE SANGYO CO., LTD.

Refer to the HMB catalog for the drainage capacity of the microbubbles.

Contact us for the capacity of the installed HMB as this is a matter of technical know-how.

Both underwater and land installation types are available. Consult us with your specifications.